We’re happy to announce the successful completion of another milestone in our research history - the AIDEAS project has come to an end. The project tackled one of the most pressing industrial challenges of our time: how to harness advanced AI to make industrial machinery and production processes smarter, more efficient, and more sustainable throughout its entire lifecycle.

A diverse team of interdisciplinary experts joined forces to develop 15 AI-based solutions, organized into four core modules covering the full product lifecycle:

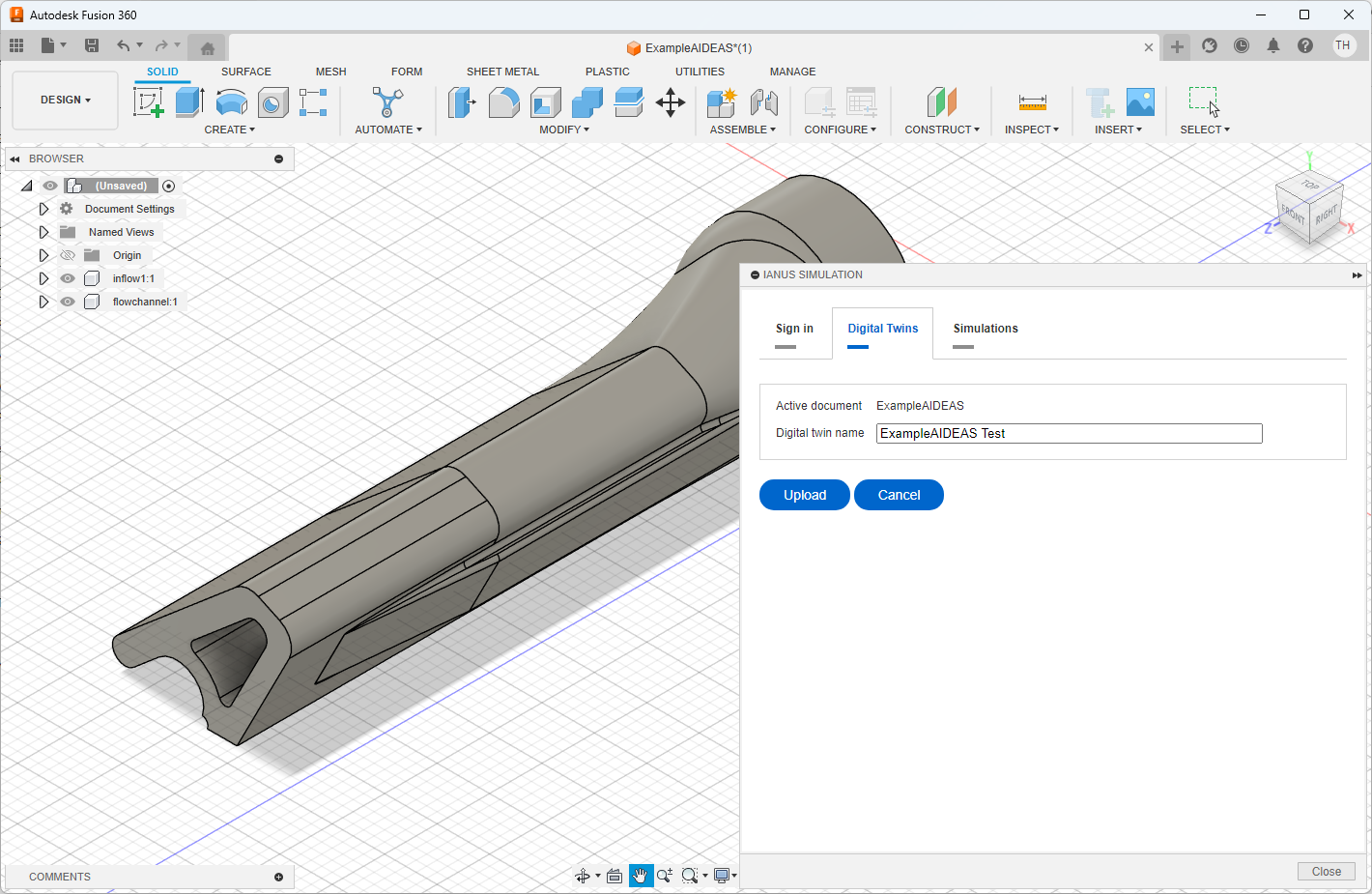

- Design: AI tools integrated into CAD/CAM/CAE systems to help engineers create better designs faster.

- Manufacturing: AI-driven insights to improve production planning, quality control, and workflow efficiency.

- Use: Smart systems for predictive maintenance and operational efficiency.

- Repair-Reuse-Recycle: AI engines that extend machinery life and guide sustainable end-of-life decisions.

These solutions were tested in real industrial settings, including metalworking, plastic forming, stone cutting, and food-sector machinery. Across the pilots, the AI tools reduced material waste, improved maintenance planning, supported more efficient design workflows, and helped manufacturers make smarted decisions about machine longevity and reuse - firmly placing AI at the heart of modern manufacturing strategy.

Real achievements that matter

AIDEAS delivered a set of concrete technological advances with measurable benefits:

- AI-enhanced design and optimization tools that reduced engineering time and material waste.

- Predictive maintenance systems that lowered unplanned downtime and extended equipment life.

- Advanced analytics and scheduling technologies that increased productivity and reduced costs.

- Machine lifecycle intelligence to support sustainable reuse strategies and environmentally responsible recycling.

Together, these innovations strengthened industrial competitiveness while directly supporting EU’s green and digital transition goals. In addition, AI systems were designed to complement human expertise, improving working conditions by assisting engineers and operators rather than replacing them.

XLAB’s role: Turning AI research into industrial tools

Among the AIDEAS partners, XLAB emerged as a pivotal contributor. With a strong track record in applied AI and advanced software systems, XLAB brought its expertise to the consortium, focusing on two key areas:

- Quality monitoring & AI-assisted optimization

XLAB developed AI modules for monitoring the quality of manufactured products, using computer vision and machine learning to detect anomalies and enhance quality assurance across production processes.

- Productization of AI-assisted design tools

A key challenge in industrial AI projects is integration into existing engineering workflows. XLAB led the effort to embed advanced optimization modules into standard industrial design tools like CAD/CAM/CAE, bridging the gap between research prototypes and industry-ready solutions. This enabled engineers to access AI-driven insights without leaving familiar design environments.

Through these contributions, XLAB not only delivered technical software components but also helped ensure the AIDEAS solutions could be adopted in real production settings, a crucial step for long-term industrial impact.

To illustrate the challanges faced, Anja Zdovc Derbashi, XLAB AI Engineer who worked on the project, explained:

“One of the main challenges in developing the visual defect detection module was the inherent variability of natural materials. In contrast to the traditional industrial environment - where product appearance is well defined - natural materials make every individual piece unique. As a result, standard computer-vision approaches were simply not robust enough. To address this, we had to rethink our models so they could distinguish naturally occurring differences from true anomalies and still deliver reliable results on the shop floor. It’s rewarding to see the result being used as a practical tool rather than remaining a research experiment.”

Looking ahead

With the AIDEAS project now complete, its results are ready to move beyond research into wider industrial use. The AI solutions show how industrial equipment can be designed, used, and maintained in smarter and more sustainable ways.

By supporting longer machine lifetimes, lower resource use, and more efficient operations, AIDEAS contributes to a stronger and more environmentally responsible manufacturing sector in Europe. The project also demonstrates how AI can be integrated into existing industrial processes in a practical and reliable way.

For XLAB, participation in AIDEAS builds on ongoing work in areas such as secure IoT platforms, distributed AI systems, and emerging technologies, with a clear focus on delivering solutions that work in real industrial settings.

The completion of AIDEAS marks not only the end of a research project, but the start of wider adoption of AI tools that support more resilient and sustainable industries.