Benefits of High-Performance Digital Simulation and Modeling for Engineering and Manufacturing SMEs

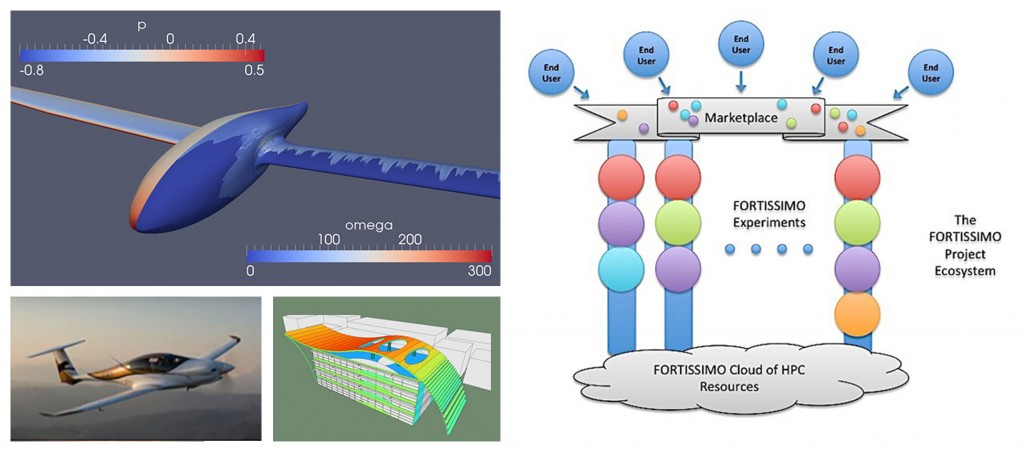

If in the past, only large companies had access to high performance computing and numerical simulation, it will now be available and affordable also to SMEs as a one-stop-pay-per-use-shop with all the hardware, expertise, applications, visualization and tools in one place. That is the purpose of the EU-funded Fortissimo project, which involves more than 45 partners, among them three Slovene companies; XLAB, Arctur and Pipistrel – the parallel software expert, HPC provider and ultra-light aircraft manufacturer as the end user, collaborating on a joint experiment Aerodynamic simulation of ultralight aircraft.

Many companies don’t make use of HPC because there is a large obstacle to overcome – high initial costs and furthermore, expensive and complicated upkeep. The simulation of, for example, high-pressure gas cylinders, molding of plastics or aerodynamics, requires enormous computing power, specialized software tools and expert knowledge. Generally, large companies have easier access to advanced simulation than SMEs, which are facing technological, expertise hurdles and financial challenges. This means that – especially engineering and manufacturing ones – are often not able to take advantage of advanced simulation, even though it would clearly make them more competitive – according to recent IDC reports, HPC servers have been closely linked to scientific advances as well as return on investments and cost savings.

Complex simulations at minimum cost

Fortissimo is designed to help companies overcome this impasse through the provision of applications and infrastructure that allows businesses to run complex simulations and calculations related to the development of new products or improvements on existing ones at minimum cost. As an alternative to expensive and time-consuming process of building, testing and improving functional prototypes, SMEs can now shift from CAPEX to OPEX by taking advantage of such resources.

HPC Cloud-based experiments

The Fortissimo project is funding a set of experiments to drive the creation and demonstrate the business potential of an HPC Cloud service ecosystem. Over 50 experiments altogether – all HPC-cloud-based – in fields such as the simulation of continuous casting and die casting, environmental control and urban planning, aerodynamic design and optimization will have been completed by the end of the project in 2016. There have been two open calls issued for participation in the experiments addressed to companies and organizations that could harvest the benefits of a HPC Cloud.

The Slovenian partner in the project, light aircraft manufacturer Pipistrel, uses HPC in an experiment to improve the fidelity of aerodynamic simulations, better predict forces acting on the airplane and gain additional information on running, handling and postprocessing big cases. On the other hand, the parallel software expert, XLAB, and HPC provider, Arctur, work on improvements of aerodynamic simulation and optimization of the HPC cloud infrastructure to ensure a positive user experience to the end user.

Success story: aircraft conceived, designed and built in a mere five months

HPC was utilized to design and develop the Taurus G4 aircraft. The team of engineers and scientist from Pipistrel has been awarded the HPC Innovation Excellence Award for relying on computer-aided design and the use of computer aerodynamics tools for evaluation of flight performance and the design of its aircraft in five months. IDC announced the recipients at the supercomputer industry conference ISC’14.

More information on Fortissimo experiments is available at: http://www.fortissimo-project.eu or [email protected]