This post was originally published on the

Techfinders.io.

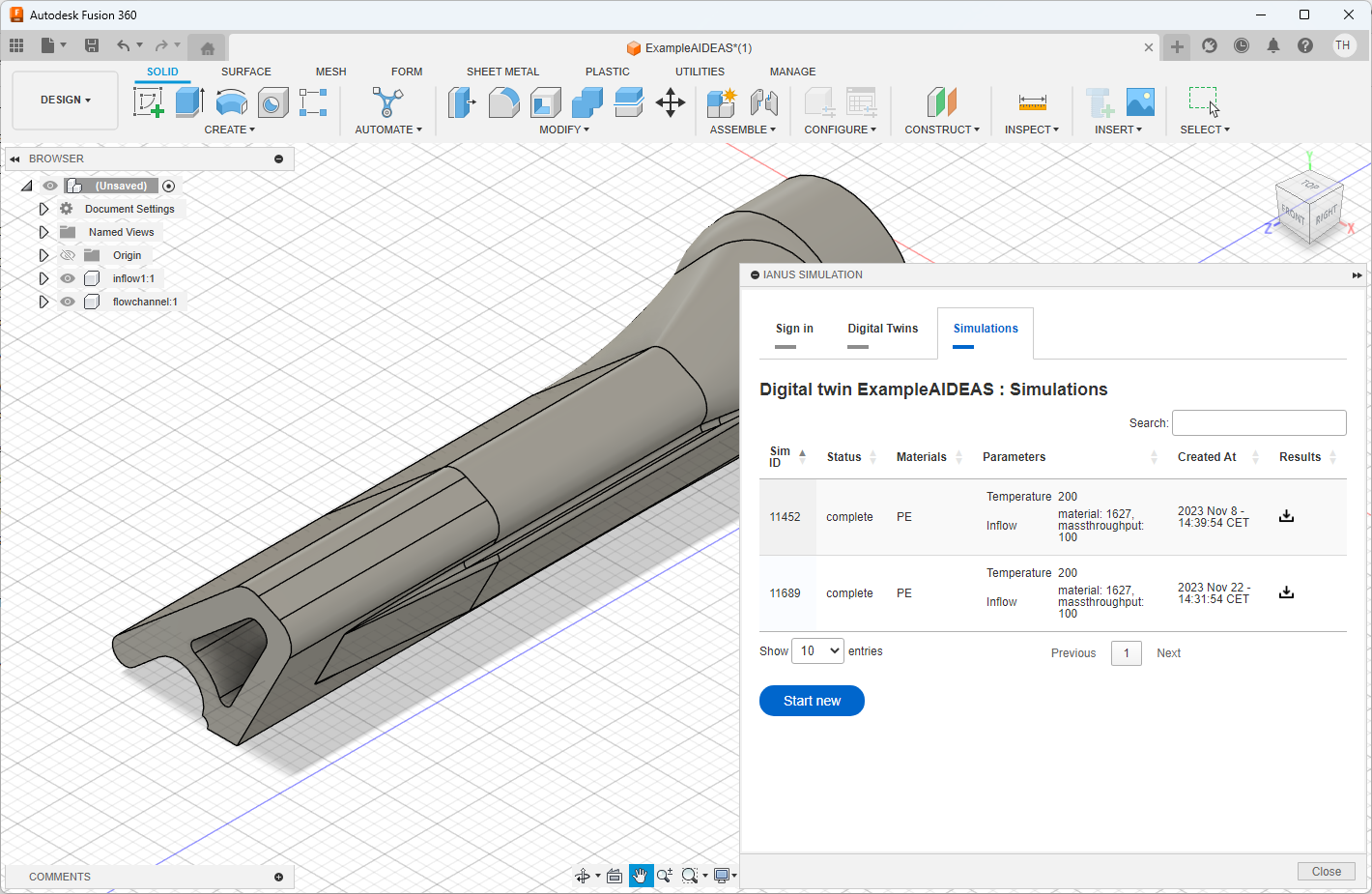

In the fast-changing world of industrial equipment design and manufacturing, using artificial intelligence (AI) is essential for boosting efficiency and driving innovation. Our research team, in collaboration with other partners in the AIDEAS project, is developing and implementing advanced AI technologies to enhance the design and manufacturing of industrial equipment. A key element of this effort is our CAx Addon, a tool that integrates AI-powered improvements directly into popular design software Autodesk Fusion 360.

The CAx Addon: A Closer Look

The CAx Addon simplifies the integration of AI-assisted optimization modules developed through the AIDEAS project, including Machine Design Optimizer (MDO) and the Machine Synthetic Data Generator (MDG), with standard CAD/CAM/CAE systems. Targeted at machine designers, process optimization engineers, and CAx developers, the CAx Addon facilitates seamless Model-to-Cloud (M2C) communication between CAx tool, components developed by AIDEAS (e.g. AI-MDG) and external tools.

Key features and functionalities

The CAx Addon offers a comprehensive suite of features that streamline the design process:

- Login and authentication: Securely sign-in to the MDO/MDG system using bearer token authentication.

- Model Upload and Digital Twin Creation: Upload 3D models in STEP format from Autodesk Fusion and create digital twins within the MDO.

- Simulation Management: Initiate, monitor, and review simulations directly within the Fusion interface. This includes listing all previous simulations, viewing parameters, and tracking the simulation status.

- Optimized Model Retrieval: Retrieve AI-optimized models from MDO/MDG and update or replace designs in Autodesk Fusion, all without needing external software.

- Notifications and Status Tracking: Get real-time updates on simulation status, job completions, and error alerts.

The core of the CAx Addon is implemented in Python, integrating with Autodesk Fusion via its API. The user interface, developed using HTML, CSS, JavaScript, and jQuery, delivers a richer user experience compared to standard Fusion UI components. The design ensures that the optimization process stays entirely within Autodesk Fusion, speeding up the design cycle and freeing up engineers to focus on refinement and innovation.

CAx Addon Version updates

TheCAx Addon is currently undergoing intensive development with frequent updates and enhancements. While Version 1.0 included essential functionalities like login capabilities, model upload, digital twin management, simulation initiation, and results downloading, Version 2.0 introduce several key upgrades:

- Directly retrieve and update optimized models directly in Autodesk Fusion from MDO/MDG.

- Enhanced job status notifications, alerting users of any simulation status changes.

- A new notification UI for success and error messages, such as digital twin creation or simulation job submissions.

- Option to delete digital twins.

- Improved UI/UX design for better navigation and user experience.

V2.0 is currently being extensively tested, and we are already planning several improvements like:

- Near real-time progress tracking,

- Additional simulation controls,

- Further UI integrations

This will make the addon even more user firendly and coupled with Fusion360.

Supporting the European Machinery Industry

The European machinery industry, employing around 3.2 million employees, is crucial to the EU economy. As part of the AIDEAS project, XLAB is contributing to the development and deployment of AI technologies to enhance the sustainability, agility, and resilience of this sector. Our goal is to ensure that AI technologies are accessible to all players, promoting global competitiveness and industrial autonomy.

By integrating AI with existing CAD/CAM/CAE systems, AIDEAS is creating a streamlined pathway for optimizing machine design, manufacturing, and lifecycle management. Our work with the CAx Addon is part of the larger effort to support every stage of the industrial equipment lifecycle – from design and manufacturing to use, repair, reuse, and recycling.

As we continue to develop and refine these technologies, we look forward to further innovations that will shape the future of industrial machinery design.

Learn more about the project and XLAB’s role here.

Take a look at how PAMA is implementing AIDEAS technologies here.

Want to learn more about these solutions? Join the AIDEAS community and connect with over 2500 researchers, manufacturers and organizations from all over Europe.